FIBC Products

Our wide range of products makes us the jumbo bag manufacturer of choice the world over. Complete product range, coupled with high hygiene standards makes iSB Exim a respected name as a bulk bag manufacturer. What sets us apart from other jumbo bag manufacturers is our ability to make custom solutions. Our UN FIBCs are certified to meet the requirements of packaging UN approved, or Hazardous Goods bulk bags are designed to comply with the United Nations Recommendations on the Transportation of Dangerous Materials.

Further to the successful performance with food grade FIBC and pharma grade FIBC.

FIBC Products

- FIBC Bags

- UN FIBC Bags

- Conductive FIBC Bags

- Dissipative FIBC Bags

- FIBC Liners

- Food Grade FIBC

- Pharma Grade FIBC

- Container Liners

Manufacturing Capabilities

- First plant with Auto-Doffing Winders

- Looms with Ultrasonic cutting

- Circular & Sulzer Looms to serve multiple needs

- Producing 1, 00,000 sq. mtr. fabric every day in Dust Free & clean Environment

- Lamination plant is equipped with brushing and dust removal

- System to ensure a very clean laminated (coated) fabric

- 7 Layer Liner plant with 0.3 micron filtered air cooling

Ionized air-wash units to ensure that finished FIBCs are Contamination free - HEPA Filtration of 0.3 microns is used to ensure absolute contaminant free for Pharma bags

- In house Printing facility

- Dust removal along with Carona Treatment for better bonding

- Perfect Square Pallets to stack 24 pallets in 20 fcl & 48 pallets in 40 fcl

Quality & Hygiene Edge

- Strict compliance with:

HACCP

BRC

AIB - Each & every bag is vacuum cleaned

- Positive air pressure maintained

- Bags are stitched in complete clean room environment with 5 micron filtered air environment

- Bales are stretch wrapped and subsequently covered with PP Cover

- Nothing is kept on floor, everything is stacked on GI stands

- 100% metal detection done for Food/Pharma grade bags

- Ultrasonic cut fabric to prevent tape fraying for Food/Pharma Bags

- Insulation Testing done for Conductive fabric/Type ‘C’ FIBC

- QUV testing done using UVB-313 Lamp

- MFI (melt flow index) tested for raw material

- Dart Impact Testing done for Liner

- Tensile Testing done for Fabric and Loops

- Straight Top Lift Testing done for FIBC

- Sewing Machines with Embedded Heat-cutting units

- Sewing Machines have Embedded Vacuum systems to prevent loose thread contamination

- MOCON Testing Machine

- QUV Weathering Testing Machine

- UTM

- Breakdown voltage testing machine

- Haze guard eye

- FTIR and UV vis Spectrophotometer

- Dart impact and UV testing machine

Types of FIBC Bags

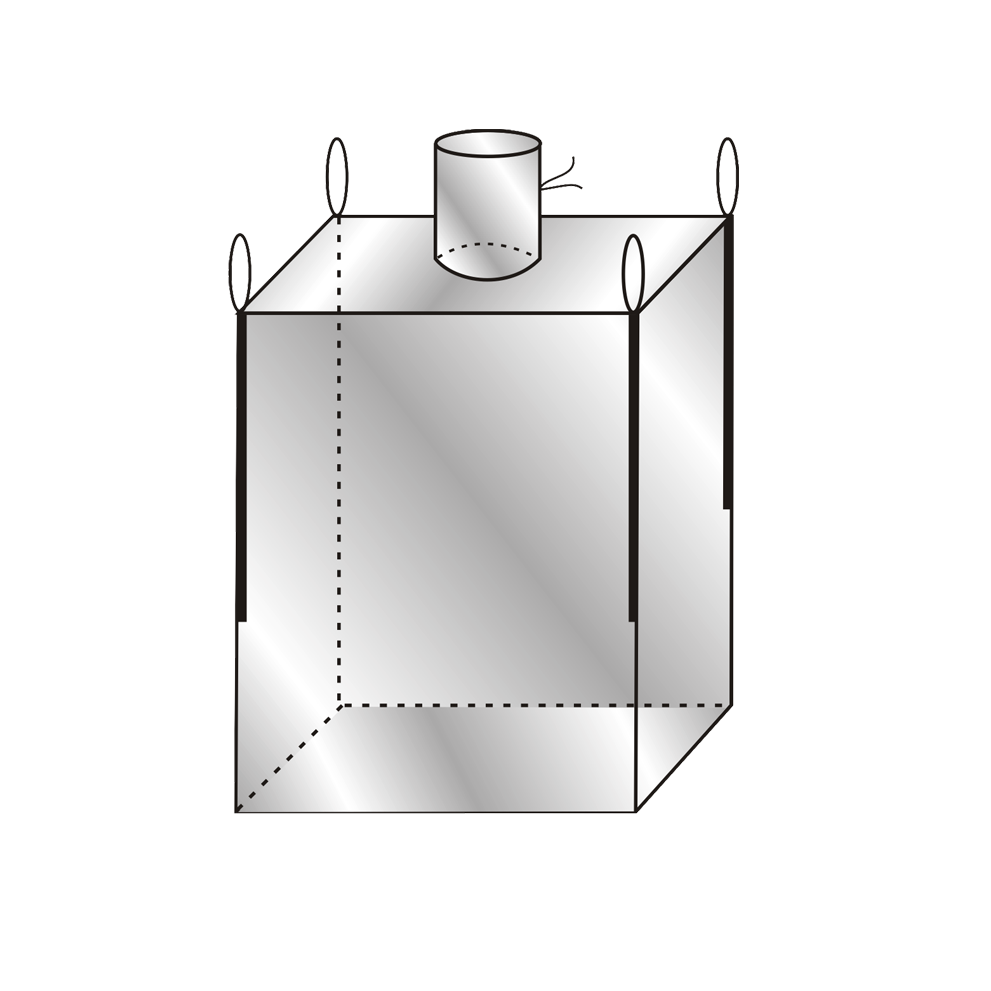

FIBC Bags

Bulk bags, also known as flexible intermediate bulk containers (FIBC) or jumbo bags, are economical and ideal packaging used for storage and transportation of powder, granular or bulk products. FIBC bags are made of polypropylene woven fabric that is stable against UV degradation

UN FIBC Bags

To meet your customized shipping needs, ISB Exim designs UN FIBC bags that are certified by the United Nations to handle products identified as hazardous. In the interests of public safety, environmental control and material safety, the transport of hazardous goods has been regulated by a team of UN experts.

Type C Bags (Conductive Bags)

Also known as a Conductive FIBC bag, this type of C bag was originally made entirely of conductive material. But today, Sage FIBC offers Type C FIBC bags that are usually made of non-conductive polypropylene woven in a grid pattern with carrying yarn.

Type D Bags (Antistatic FIBC)

Made from special antistatic fabric, the anti-static bulk bag on ISB Exim comes with permanent discharge properties and is designed to prevent the spread of flammable sparks, brush discharges and brush discharges without attaching the bulk bag to the ground or earth.

FIBC Liners

Liners can be inserted loosely or even attached to a bag. There are different types of liners for different applications like form fit liners, tubular liners, food-grade liners.

Food Grade FIBC

Food grade bulk bags are made with resins meeting FDA standards with the intent of putting food products into the bags. Food grade FIBCs are manufactured in a clean room facility that can be certified by a food safety standard like SQF, AIB, and/or BRC.

Pharma Grade FIBC

Pharma grade FIBC is used for storage of pharmaceutical products and since they provide safeguard against contamination. Pharma grade FIBC protects pharmaceuticals from dust and other foreign particles and hence can be used for transportation of medical products.

Container Liners

Food grade bulk bags are made with resins meeting FDA standards with the intent of putting food products into the bags. Food grade FIBCs are manufactured in a clean room facility that can be certified by a food safety standard like SQF, AIB, and/or BRC.